ISO Class Cleanroom Wipes At TIDDOX

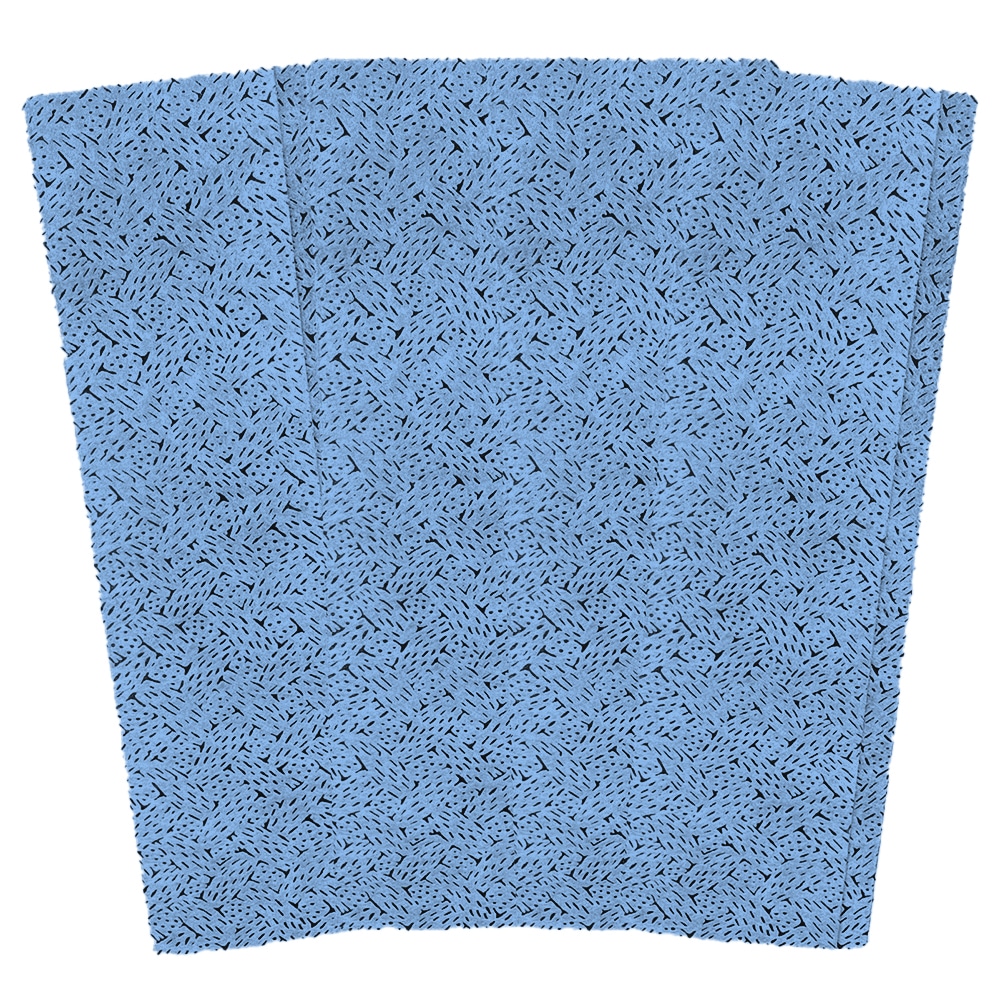

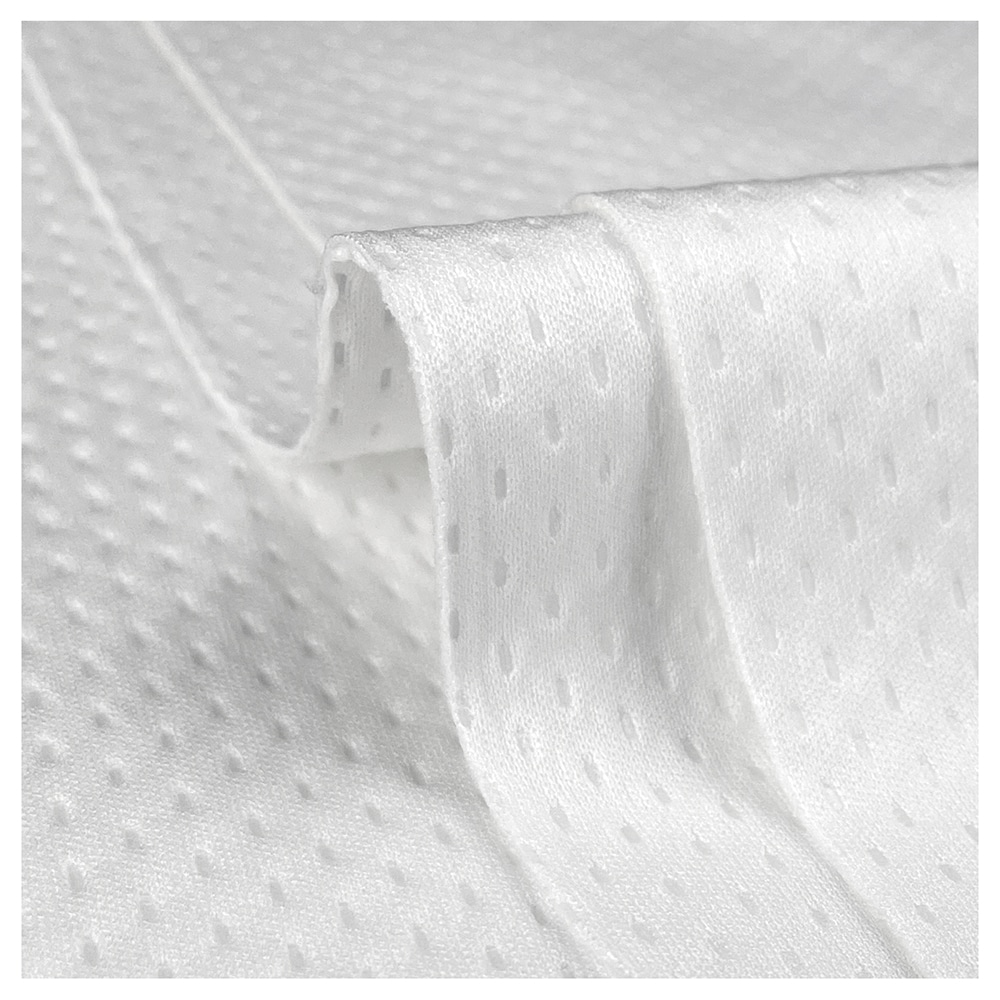

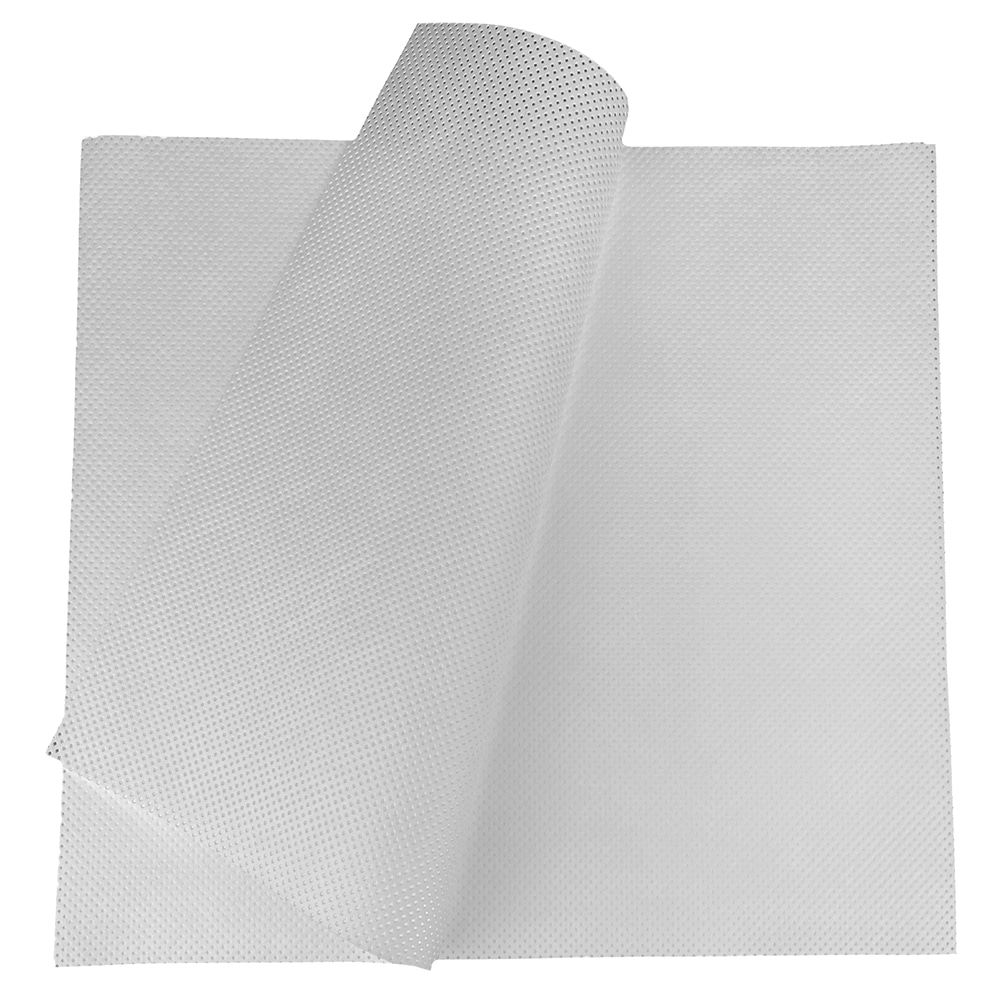

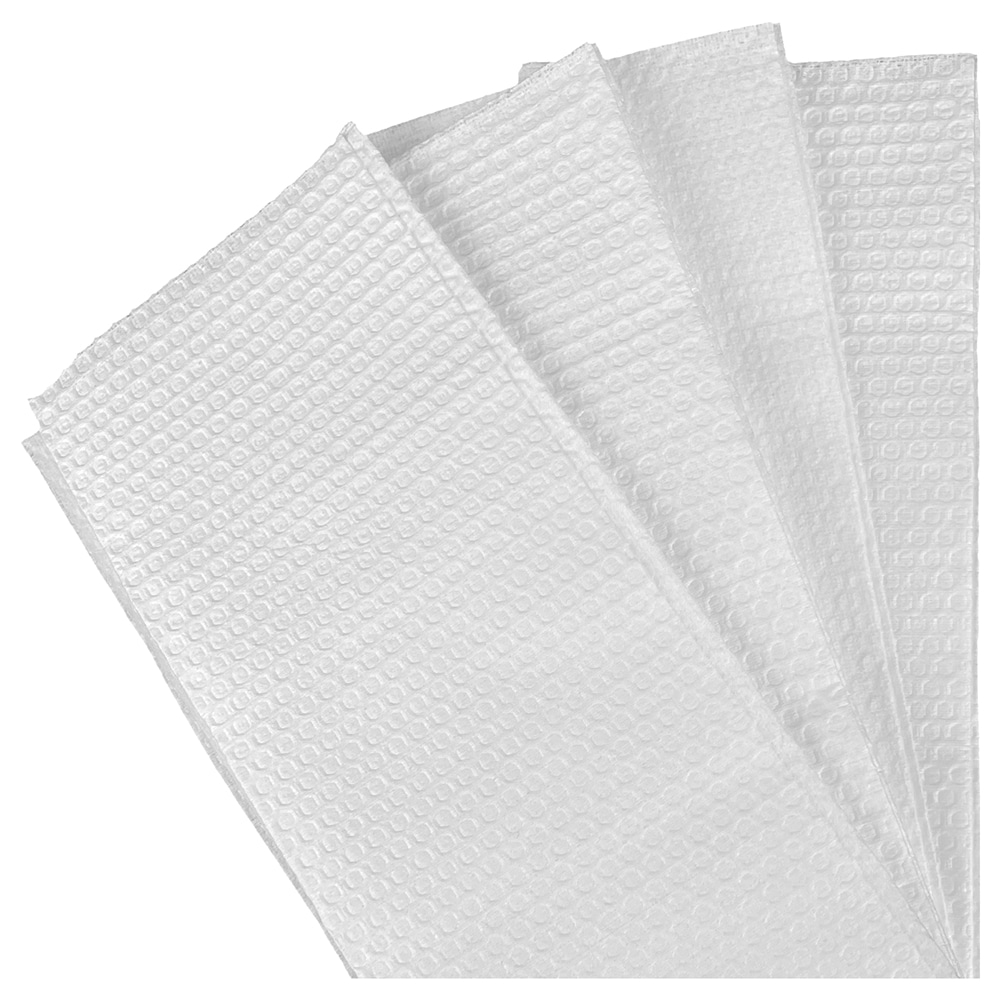

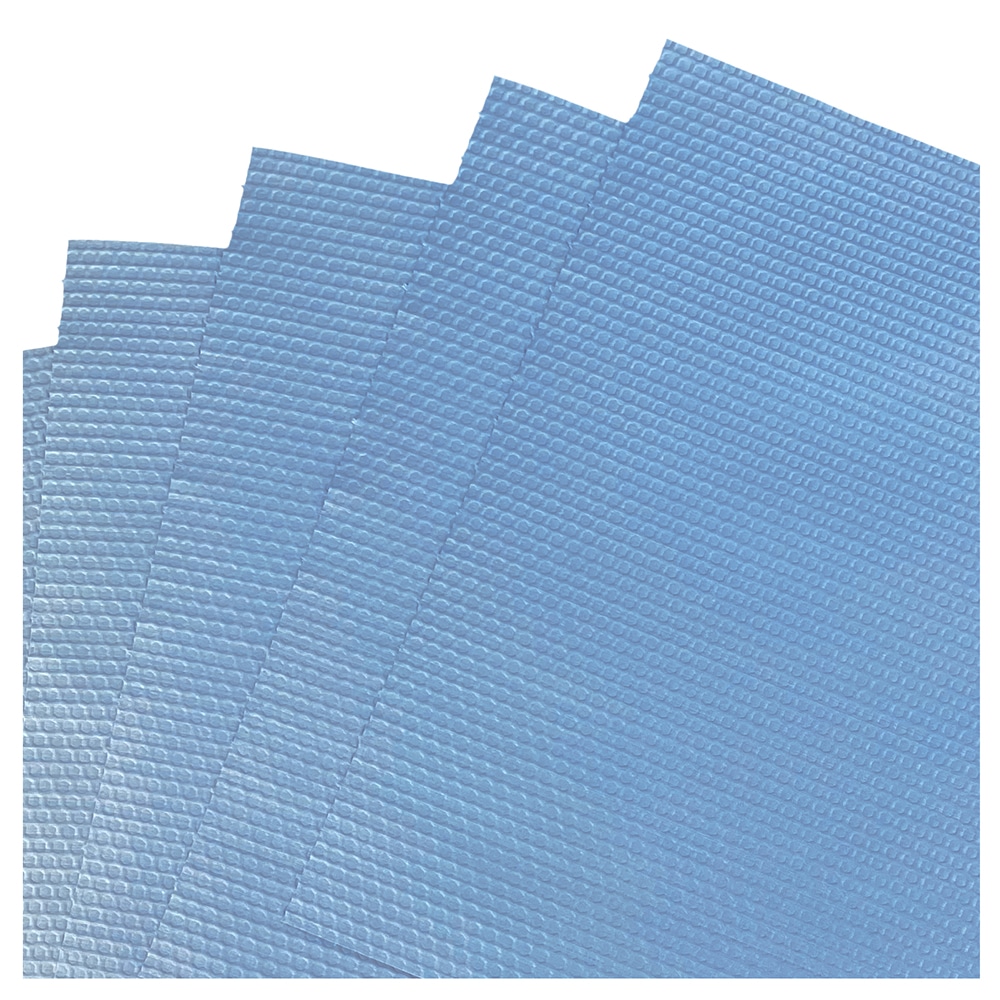

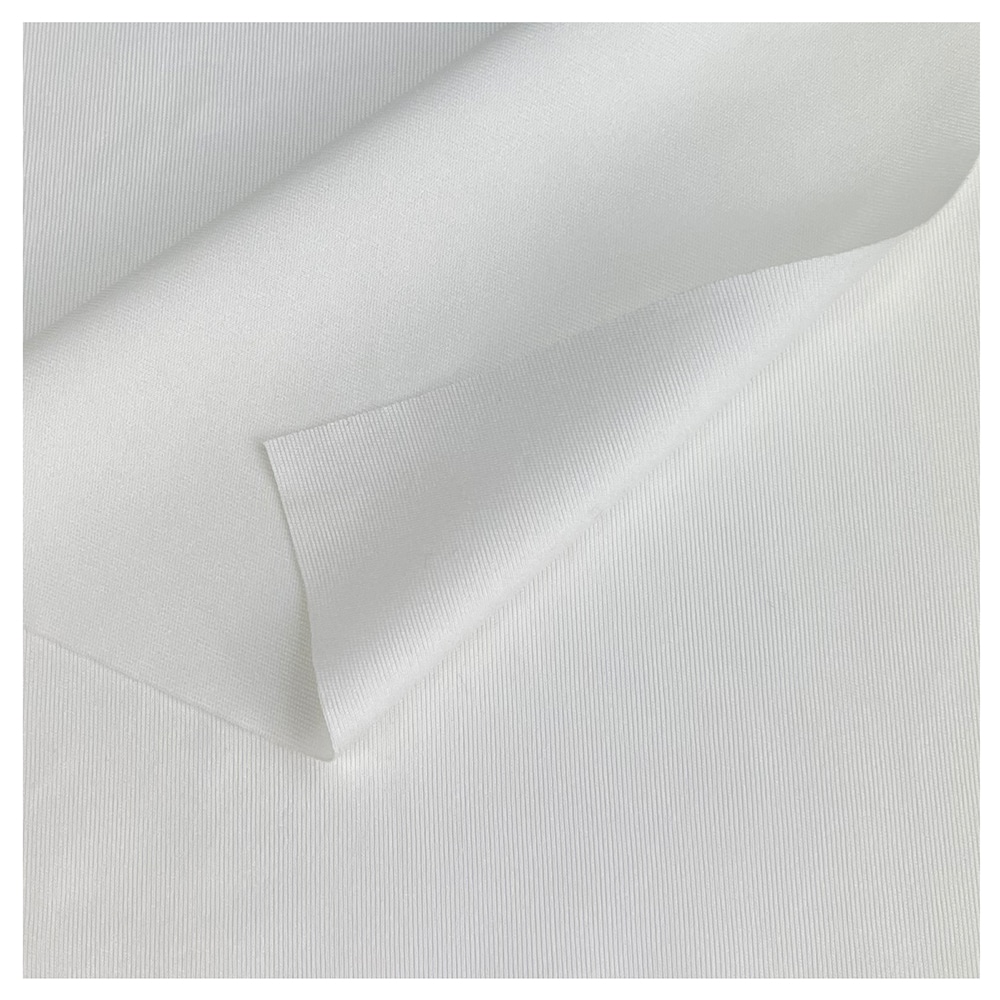

ISO class cleanroom wipes are an essential tool in maintaining the cleanliness and sterility of cleanrooms. These wipes are specifically designed to meet the requirements of different ISO classes, ensuring that the cleanroom environment remains free from contaminants. Cleanrooms are used in various industries, such as pharmaceuticals, electronics, and healthcare, where maintaining a sterile and controlled environment is crucial. Cleanroom wipes are made from high-quality materials that are non-shedding and low-linting. This ensures that the wipes do not introduce any additional contaminants into the cleanroom.

A cleanroom is a controlled environment that is specially designed to minimise the presence of airborne particles, contaminants, and pollutants. It is typically used in industries where strict cleanliness and hygiene standards are required, such as pharmaceuticals, electronics, and biotechnology. Cleanrooms are constructed using specialised materials and techniques to achieve a high level of cleanliness. They are equipped with advanced air filtration systems and are maintained at a positive pressure to prevent the entry of contaminants from outside.

The ISO class of a cleanroom refers to the level of cleanliness that it must maintain. The higher the ISO class number, the cleaner the environment needs to be. Regular cleaning with these wipes helps to maintain the cleanliness and sterility of cleanrooms in various industries. Cleanrooms are classified based on the maximum allowable number of particles per cubic metre of air, with Class 1 being the cleanest and Class 9 being the least clean.

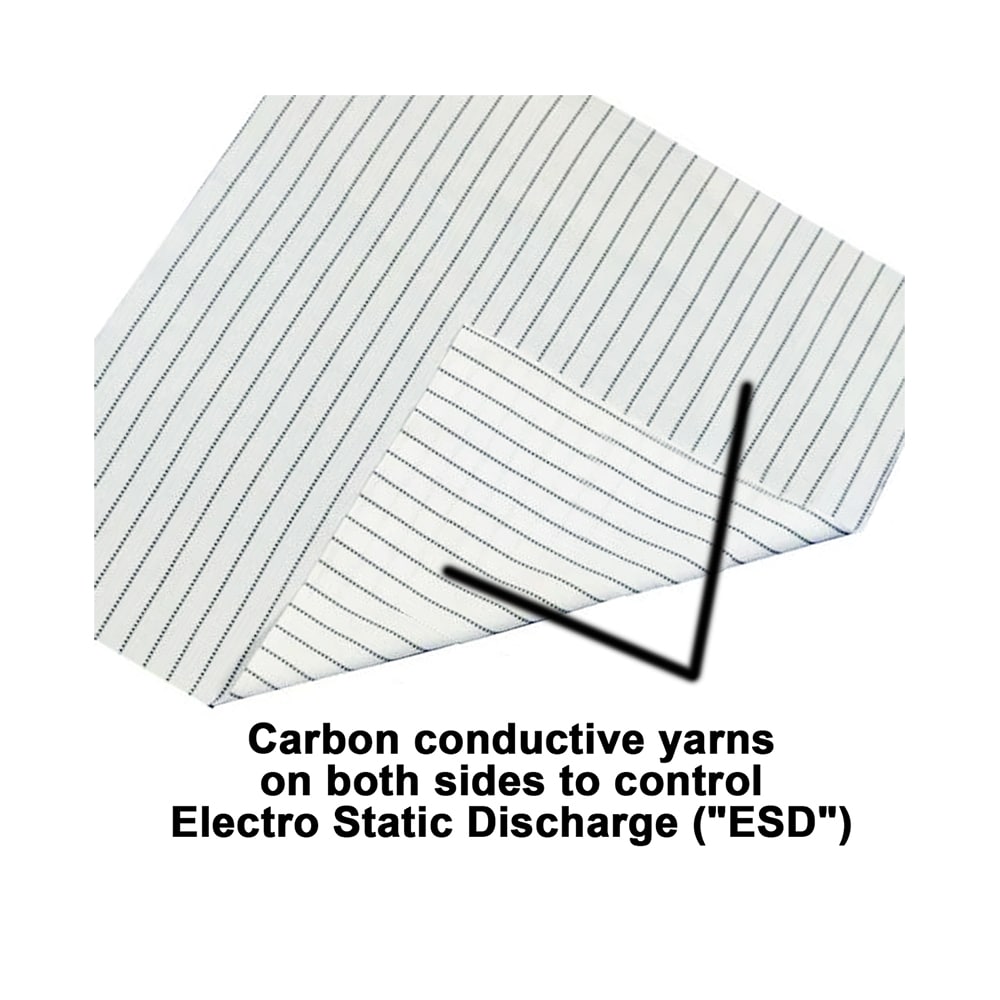

They are made of different materials, depending on their intended use. The most common materials used for cleanroom wipes are polyester, polypropylene, and cellulose.